[Plastic molded product take-out robot x Image inspection machine] Automating the appearance inspection of plastic molding lines to promote labor savings in Thailand!

We are an expert in appearance inspection and image processing inspection. We provide total image inspection solutions that meet the needs of our customers. We have collaborated with Yushin Precision Equipment, a pioneer of plastic molded product take-out robots, to build an innovative automation line in Thailand. In this article, we will introduce the benefits of this project.

Take-out robots offer a wide range of possibilities for automation.

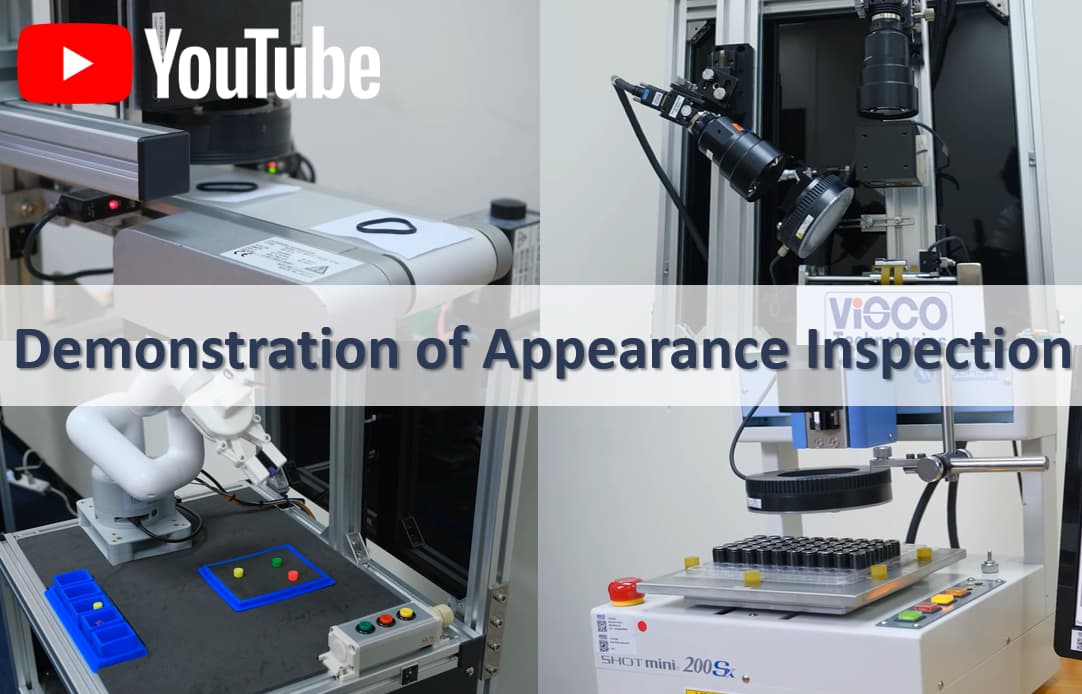

In recent years, there has been a rapid increase in automation using plastic molded product take-out robots. For example, there are cases where insert molding, gate cutting, and gate crushing are combined. And now, as a new initiative, ViSCO Technologies' image inspection machines and Yushin Precision Equipment's molded product take-out robots are collaborating.

No need to invest in new equipment, saving resources, and other benefits for implementation

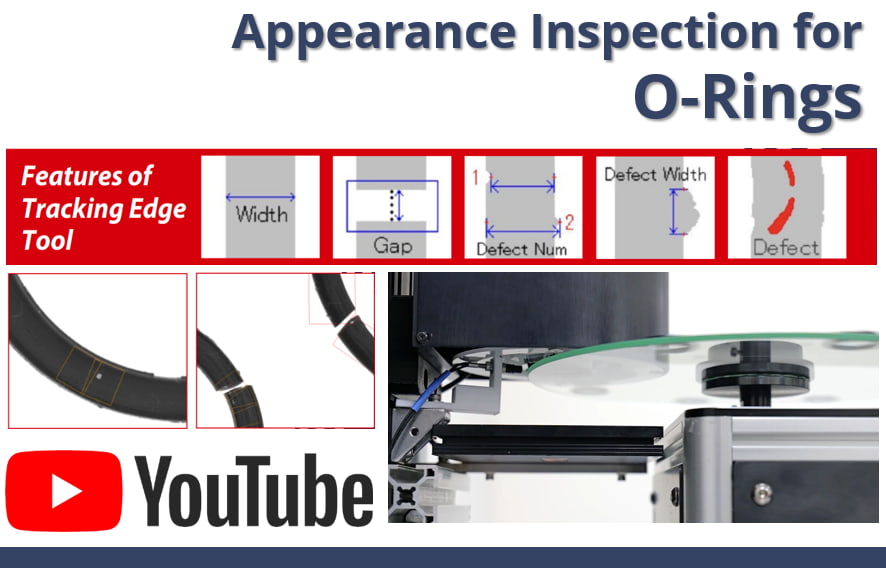

Specifically, our image inspection machine VTV-9000 inspects molding defects such as short shots and burrs, as well as gate cutting defects, while the workpiece is being held by the molded product take-out robot.

This will provide the following benefits:

- ➀ Shortening work time Since the inspection is performed while the molded product taking-out robot holds the workpiece, defective products can be eliminated at an early stage, and appearance inspection can be omitted in the subsequent process.

- ➁ Reduction of on-site workers Workpiece take-out, transportation, and inspection are completed in single operation. The number of workers involved in the operation can be reduced.

- ➂ No new equipment required An image inspection machine can be added to the existing molded product take-out robot. The cost is less than half that of newly manufactured equipment with the same functions.

- ➃ Cost reduction Improved work efficiency can shorten time and reduce manpower. Significantly reduce related costs.

Proposing the best combination to meet customer needs

For the implementation in Thailand, Yushin Precision Equipment's "SD series", which is equipped with the same technology as the high-end model with high speed and excellent vibration control, was used for the plastic molded product take-out robot. Although it is economical, it is made in Japan and has outstanding rigidity and durability.

Yushin Precision Equipment (Thailand) is the only manufacturer in Thailand that sells injection-molded product take-out robots that are exclusively made in Japan.

For the image inspection machine VTV-9000, ViSCO Technologies (Thailand) will propose the optimum camera, lens, lighting, etc. in total, and handle the entire process from start-up. Please leave it to us with peace of mind.

For inquiries regarding automation that combines a plastic molded product take-out robot and an image inspection machine in Thailand, please contact us using the inquiry form below.

Please Wait

Please Wait

Office

Tel: +66(0)2-664-3236

Email: sales@visco-tech.co.th