In metal processing such as cutting and casting, a major issue is the step of removing "burrs" that are metal residues (burr removal). It is not an exaggeration to say that metalworking is a battle with burrs because it is a work that can determine the accuracy and quality of products. For this reason, many attempts have been made at the manufacturing sites to find ways to remove burrs easily and completely.

This time we will introduce an epoch-making product that can solve such a trouble instantly. Let us introduce the "iTEM series" produced by ATL Company from Germany, which can explode natural gas (CNG / LNG) and removes burrs at once.

The good thing about the iTEM series is the ease of operation. You can simply place an object on the built-in rotary table and set the ratio of gas flow amount and mixed gas on the touch screen. Then, the mixed LNG gas is plug-ignited and explodes in the combustion chamber. It becomes a high temperature with a high pressure state of 2500-3000 ℃, oxidizes burrs by electric heat energy obtained from the combustion, and eliminates the burrs instantly. Average processing time is about 2 minutes including transportation. It is very easy to get smooth finished products without burrs.

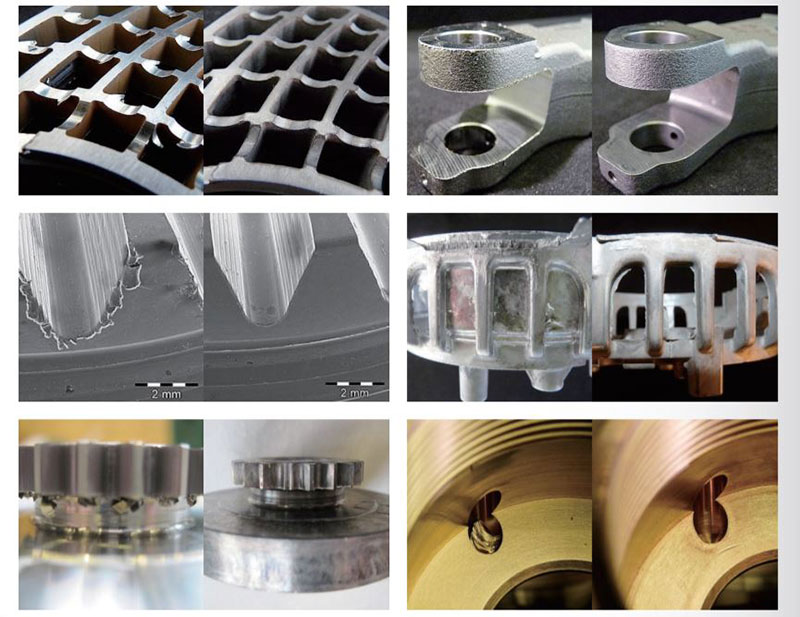

The structure is similar to that of a 4-cycle vehicle engine and the characteristic is that the combustion energy spreads to every corner of the combustion chamber. As a result, it is easy to remove burrs in the hydraulic components with complicated and multiport tolerance holes and die-casting components used in automobile internal combustion engines evenly. The gas is under full control by the control unit, and it is perfectly safe because it is covered in a special cabinet together with the combustion chamber.

We can handle most metal materials such as cast iron and aluminum, and it is possible to deburr some resin products. We are confident that the machine can ensure the optimal and elaborate finish because gas flow rates and mixing ratios are well programmed. No special expertise or special training is required. However, you should be careful with thin or less-strong objects because the explosion may deform or damage them.

The mechanism of deburring using the explosive energy of gas is called a "Thermal deburring" system. Only a handful of manufacturers in the world can produce deburring machines using this method. Above all, ATL's advanced technology is well-known around the world.

In Thailand, localization of both high-precision hydraulic mechanism parts and die-cast parts has gradually been introduced. We often receive many inquiries if "there is a machine that can easily remove burrs." For these reasons, the iTEM series has been launched in the market in Thailand. We are actually a company that has a role as a distributing agent. We will provide one-stop service from after-sales services including maintenance and inspection and repair to offering combinations with wearable loading / unloading robots and the iTEM series.

■ If you have any problems in deburring, or if you are interested in ALT's "iTEM series" deburring equipment, please contact us using the form below.

Please Wait

Please Wait

Office

Tel: +66(0)2-173-5868

Watanabe

Mobile: +66(0)61-847-4400

Email:

watanabe1001@ykt-thailand.co.th

Podsatorn Promdang

Mobile: +66(0)61-847-4443

Email:

podsatorn0004@ykt-thailand.co.th